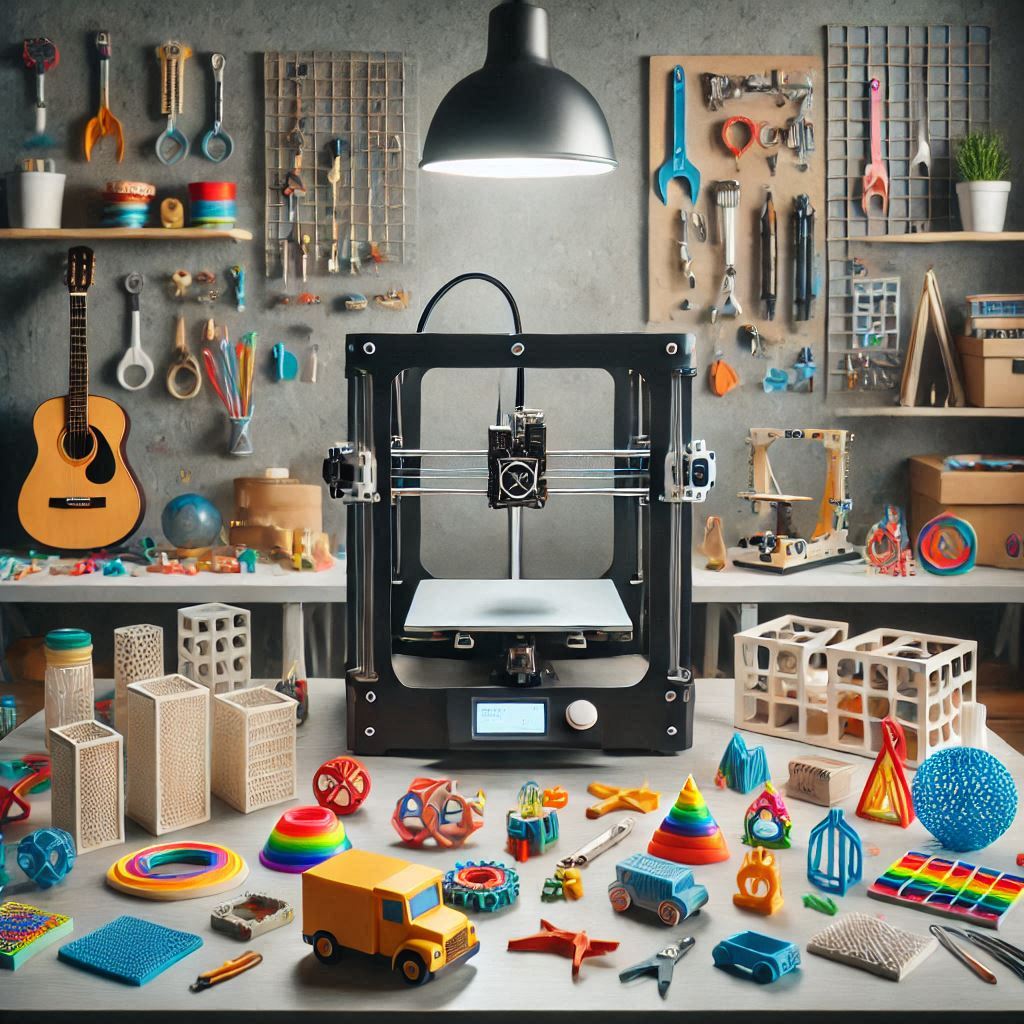

Welcome to the future of manufacturing! 3D printing, also known as additive manufacturing, has taken the world by storm. This innovative technology allows for the creation of three-dimensional objects layer by layer, based on a digital model. It’s a game-changer in various industries, offering endless possibilities and transforming the way we design, create, and produce.

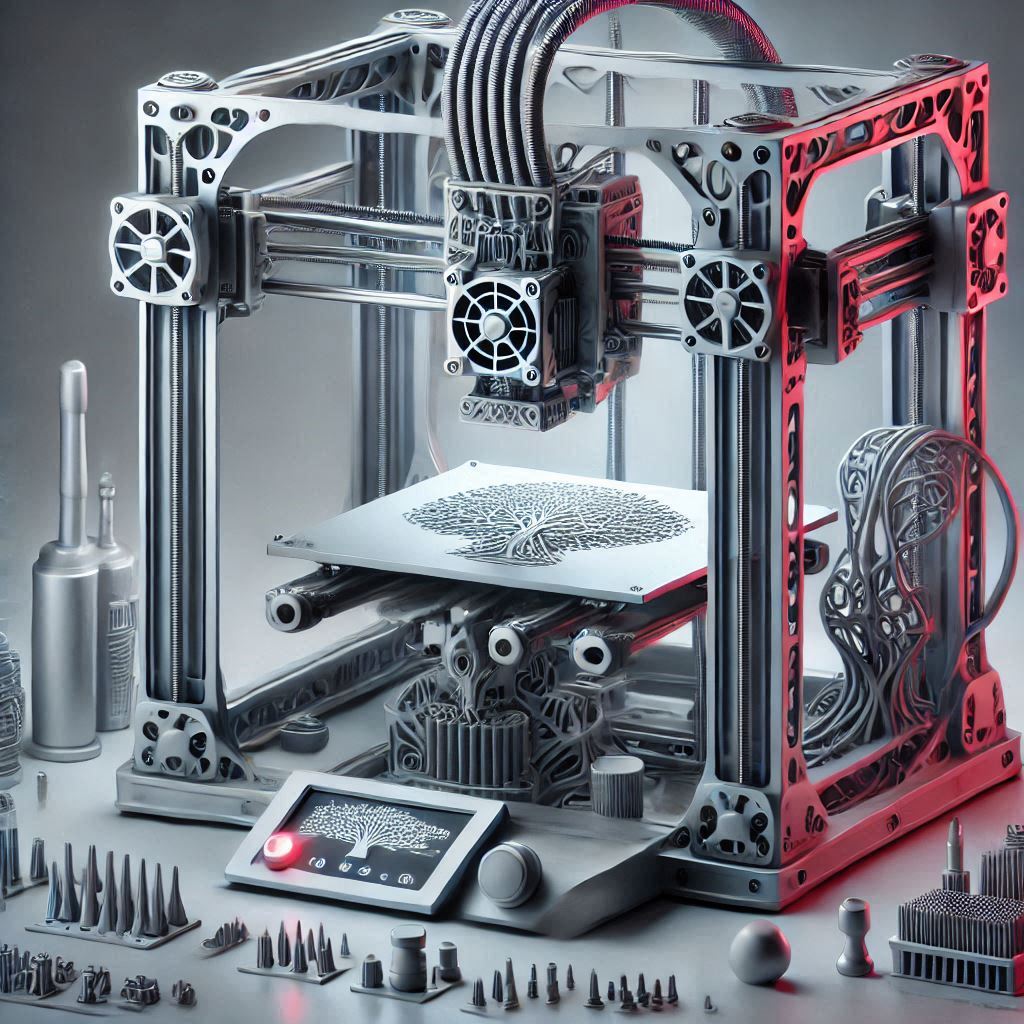

Understanding 3D Printing: At its core, 3D printing involves the use of a 3D printer, which reads a digital file (usually in formats like .STL or .OBJ) and deposits materials such as plastic, metal, or resin, layer by layer, to build the final object. Unlike traditional subtractive manufacturing, which removes material to create shapes, 3D printing adds material, allowing for intricate and complex designs that were previously impossible or too costly to produce.

One of the most notable impacts of 3D printing is in the medical field. Surgeons can now create patient-specific implants and prosthetics, enhancing the precision and effectiveness of medical treatments. Additionally, the advent of bioprinting, which involves printing with bio-ink made from living cells, holds the promise of fabricating complex tissues and organs for transplantation.

In the manufacturing sector, 3D printing enables the production of complex geometries that are difficult or impossible to achieve with traditional methods. This not only accelerates prototyping but also allows for on-demand manufacturing, reducing the need for large inventories and minimizing waste. Companies in the aerospace and automotive industries are leveraging 3D printing to produce lightweight and durable parts, leading to more efficient and sustainable transportation solutions.

Types of 3D Printing:

Fused Deposition Modeling (FDM): This is the most common type of 3D printing. It uses thermoplastic filaments, which are melted and extruded through a nozzle to build objects layer by layer

Stereolithography (SLA): SLA uses a UV laser to cure liquid resin into solid objects. This method is known for its high precision and smooth surface finishes.

Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered material, fusing it layer by layer to create solid structures. It is often used for producing durable and complex parts.

Applications of 3D Printing

The versatility of 3D printing has led to its adoption across multiple industries:

Prototyping and Product Development: Rapid prototyping allows designers and engineers to quickly create and test models, speeding up the product development process.

Healthcare: Customized prosthetics, dental implants, and even bioprinted tissues and organs are being developed using 3D printing technology.

Manufacturing: From aerospace to automotive, 3D printing is used to produce lightweight, high-strength components with complex geometries.

Fashion and Art: Designers and artists are leveraging 3D printing to create unique, intricate designs in fashion, jewelry, and sculpture.

Construction: The construction industry is exploring the use of large-scale 3D printers to build houses and structures more efficiently and sustainably.

Key Components of 3D Printing in Construction

- Materials Used:

- Concrete: The most common material used in construction 3D printing. Special formulations of concrete are designed to be extruded smoothly and set quickly.

- Polymers and Composites: Used for specific parts or in conjunction with concrete to enhance strength and flexibility.

- Metals: In some advanced applications, metals like steel can be 3D printed for structural components.

- 3D Printers:

- Robotic Arms: Equipped with extruders to lay down material layer by layer.

- Gantry Systems: Large-scale printers with a frame that moves along multiple axes to construct large structures.

- Mobile Printers: Portable printers that can be transported to different construction sites.

- Process:

- Design: A digital model of the structure is created using CAD (Computer-Aided Design) software.

- Slicing: The digital model is sliced into layers that the printer will use to build the structure.

- Printing: The printer extrudes material according to the design, building up the structure layer by layer.

- Post-Processing: Additional steps like curing, smoothing, and finishing touches are applied to ensure structural integrity and aesthetics.

Challenges and Future Prospects

While 3D printing offers incredible opportunities, it also faces several challenges:

Material Limitations: The range of materials suitable for 3D printing is still limited. Developing new materials is an ongoing area of research.

Speed and Cost: 3D printing can be slower and more expensive than traditional manufacturing for large-scale production.

Quality Control: Ensuring consistent quality and reliability in 3D-printed parts remains a challenge.

Future Prospects: The future of 3D printing is incredibly exciting, with advancements in materials, speed, and precision. Emerging trends such as bioprinting, 4D printing (where objects can change shape over time), and the use of sustainable materials promise to push the boundaries of what is possible

3D printing is revolutionizing the way we design and manufacture, offering new possibilities and efficiencies across various industries. As the technology continues to evolve, the future of 3D printing holds endless potential, paving the way for innovations that were once the stuff of science fiction.

3D printing has finally broken away from cartesian 3-axis in a way that makes sense. Designed from the ground up, not a rotating bolt-on print head. Unlimited overhangs, offboard part cooling fan via an air compressor, and open source with slicer included 😲 pic.twitter.com/nS0tne4WJ3

— Eric 🐇 (@Mammoth) December 1, 2024

Subscribe to our newsletter!